|

The 15cm. schwere Feld Haubitze (s.F.H.) 1913 was the first heavy howitzer fitted with a shield. The hydo-spring recoil mechanism perfected with the “02 gave the engineers at Krupp the confidence to incorporate this protective feature into the “13. With heavy Foot Artillery now in a maneuver support role this addition also made sense

|

The 15cm s.F.H. 1913 was in service with both German and Ottoman/Turkish Heavy Artillery units throughout World War I

|

*This s.F.H.”13 was the last 15cm acquired into the

Lovett collection so is not yet restored

|

Development of the 15cm.s.F.H. 1913

(by CW2 Ralph Lovett)

Before the war interest grew in Germany for a heavy field howitzer with a shield. This required that the howitzer remain steady when firing. Otherwise, the crew could not stay covered behind its armor during recoil. Tests the APK conducted using loose shields, placed beside the howitzer, had failed. They had not been able to stand the strong muzzle blast generated upon firing. The weight of this extra armor also made them impractical to carry along and emplace. To provide steadiness during firing it was necessary to increase the length of recoil. In 1907 the APK was determined to propose a new 15cm howitzer with a protective shield. However, this created much controversy. The same old argument flared up again as to whether, after the introduction of the light field howitzer (l.F.H. 98/09) another heavy field howitzer was necessary.16 Yet another group, among them representatives of the General Staff, wanted to have an intermediate caliber 13.5cm “common howitzer” in place of a 10.5cm. and a 15cm. combination. This group felt justified by reports presented during the introduction of the new 15cm. 04 shell. It was reported that the 04 shell had more than enough power when used against troops dug in with cover. From this report the General Staff concluded that a reduced caliber howitzer should be adopted. New tests were, however, necessitated by the recently introduced Field Fortification Regulation of 1906. Improved stronger shelters were required in these regulations, which called for a double layer of rails and an intermediate layer of earth, rails, logs or ballast.17 For several months firing test were conducted at Kummersdorf with 13.5cm. and 15cm. howitzer shells. This task consumed great amounts of ammunition due to the fact that direct target hits were required. The coverings constructed according to the 1906 Regulations were not penetrated by the 15cm. 04 shell. A 40 kg. shell with a 6 to 7 kg. explosive was found to be necessary to achieve effects on covered shelters. The same conclusion was reached as in the 1891 test between the 12cm. and the 15cm. howitzer shells. A 13.5cm. shell would have to be much to long to carry the necessary explosive charge, and accuracy would suffer. From 1908 to 1910 additional tests were conducted to determine effects on field coverings. The target shelters tested were 50 cm. concrete on wooden or earth pad; 60cm. reinforced concrete; 80cm. gravel concrete on T-girders; 1.08 m. concrete, special mixture on double rails; 1. m. gravel concrete on corrugated sheet metal; 80cm. ballast concrete, set for 14 days. 15cm. shells with explosive charges form 5.5, 6 and 8.2 kg. base fused with hardened noses were even unable to penetrate any of these coverings. These tests proved the need for 21cm. shells when concrete shelters over 50cm in thickness were targeted.18 The 21cm. shell’s effects ended at a concrete thickness of 1 meter if single round penetration was required. The tests were carried on using shells of larger caliber up to the 42 cm. mortar, and afterwards test were conducted to determine the effect of large explosive charges. These tests formed the basis for the list of norms or something like our Joint Munitions Effectiveness Manual for high angle howitzers.19

In a report dated 17 December 1908 the APK presented design requirements for a new 15 cm. howitzer. It was specified that weight of the gun in firing position should not exceed 2100 kg. and in traveling configuration 2700 kg. Mobility should at least equal the s.F.H. “02. The howitzer was required to have a range of 8000 m. with projectile weight of 40 kg.20 Shield thickness of 3 mm. and height from the ground of 2 m. was required. The howitzer was to remain at rest when fired with the smallest charge at an elevation of 0 degrees and when all charges are used from about 18 degrees. Carriage length from the axle to the tip of the folding spade should be no more than 3.3 m. Range of elevation should be 0 degrees to 45 degrees and traverse at least 2.5 degrees to each side. Required also was a sighting arrangement with traversing and elevation wheels accessible to one crewman. Seats for number 1 and 2 gunners for sitting in firing position and common ammunition with the s.F.H. of 1893 and of 1902 was required. The wheels were expected to be interchangeable with those of the limber. It was considered preferable that the limber accommodate at least two rounds.21

After gaining approval of the General Inspectorate of Foot Artillery and the General staff, the War Ministry gave an 11 February 1909 dated order for one test howitzer each from competing firms. The 17 December 1908 report served as the basis for this order, which went to Krupp, Heinrich Ehrhardt’s Rheinsche Metallwaren und Maschinenfabrik A.G. (Ehrhardt was a Rheinmetall official so it appears the two names are almost used interchangeably) and the A.K. As is clearly the pattern, this order provoked controversy. Those opposing the new s.F.H contended that no heavy howitzer was needed alongside the new shielded 10.5 cm. l.F.H. 98/09 and the direct fire 7.7cm. l.F.K. In response, the Inspector General of the Foot Artillery, General von Dulitz, commented “In field warfare, the artillery must keep the enemy field artillery at bay of the infantry, otherwise a large portion of the artillery is superfluous.” General von Dulitz also pointed out that the shrapnel shells of the 7,7cm. light field guns were useless as counter battery weapons against enemy shielded batteries and were of no value in their task to "keep the enemy field artillery at bay". Despite the test which had proven the 15cm. over the 13.5 cm. at Kummersdorf, more tests were ordered to determine the effects of light and heavy howitzers on shielded batteries. The test firing took place at Jueterbog in October 1910 and was based on both howitzer types having the same amount of ammunition in terms of weight. With the given ammunition the 10.5 cm.’s effects covered roughly two targeted battery positions. The 15 cm.’s effects covered between three to four targeted battery positions.22 Even with the better performance of the 15 cm., effects were considered impressive enough form the 10.5 cm. that both howitzers were concluded to be necessary. The upshot of this was, however, that the 15cm. heavy field howitzer concept proved itself yet again. Despite commanders complaining of march columns unnecessarily long, and movement too slow to keep up with the troops, heavy field artillery stayed and was developed in Germany. In France no parallel survived the fervor to re-fight the Franco-Prussian War. Participation of heavy field howitzer battalions in prewar firing exercises and maneuver field training exercises helped dispel some of these misgivings. However, grumbling of this nature could be heard from maneuver and “light” field artillery commanders right up until the war. Once the reality of combat in the Twentieth Century was seen these attitudes changed.

|

On 23 February 1911 the Rheinmetall test howitzer was accepted

for field trails. The Krupp howitzer was over the weight requirement

and was not presented. Professor Rausenberger of Krupp felt there

was much work to be done to satisfy the requirement that the howitzer

remain at rest at an angle of eighteen degrees, firing the strongest charge.

At their own expense Krupp built three new experimental howitzers. In

January 1911 these were presented to the APK. 23

The first had constant recoil, back positioned trunnions, equilibrator

and recoil brake above the tube. The second had variable recoil

and the third had constant recoil without an equilibrator. The first

howitzer was accepted on the basis of the order placed in February

1909. It was designated Krupp Test Howitzer. A Rheinmetall

design was also accepted for test and competed along side the Krupp in

firing and travel testing in the Westerwald area.24

In firing test the Rheinmetall design proved superior, however, because

of the mobility controversy weight was the primary concern for the APK.

The Rheinmetall test howitzer had variable recoil and fully used

its recoil length of 1600 mm. opposed to the Krupp’s 1200 mm. constant

recoil. Both howitzers had grown heavier than 2100 kg. and had firing

ranges of about 9250 m. Ehrhardt’s Rheinmetall howitzer

featured a loading lever, which allowed the tube to move into loading

position without interrupting laying. Both had spring recuperators

even though the APK continued to test an air recuperator at Kummersdorf,

should it become necessary later.25

On 21 May 1912, after the preliminary conclusion of the firing

and traveling test, an order for a test battery comprising four howitzers

was placed with Krupp and Rheinmetall.26

The requirements for this battery were generally identical with those

for the Test Howitzer. Regarding the Krupp several important exceptions

were noted, however. The recoil brake was to be positioned below

the tube; maximum possible stability for all tube elevations was expected

when firing normal charges. Following firing test in Russia, Krupp

engineers concluded a combination of their back-positioned tunnions with

equilibrators and the Rheinmetall style variable recoil would best met

the requirements.27

To meet these demands Krupp suggested that this test battery should be

constructed with back-positioned trunnions used in combination with a

variable recoil mechanism. The APK agreed with these suggestions

and the battery of test howitzers were accepted for firing and maneuver

test in February 1913. The two firms delivered one howitzer each

to Foot Artillery Regiment 14. This regiment used them in the autumn

maneuvers and submitted a report to the General Inspectorate of Foot Artillery

(Stassburg, 30 September 1913). This report emphasized the importance

of reducing the howitzer’s weight.28

The report of the 14th Regiment gave the following weights:

| Krupp howitzer no. 6 | 2160 kg. in firing position |

| Rheinmetall howitzer no. 2 | 2215 kg. in firing position |

| Krupp how. No. 6 ready to move | 2815 kg |

| Krupp limber | 448 kg. |

| Rheinmetall how. No. 2 ready to move | 2860 kg |

| Rheinmetall limber | 456 kg.29 |

Less than one hundred kg. difference in weight

turned the decision in favor of the Krupp Test Howitzer and on 22 November

1913 the AKO (Supreme Cabinet Order) introduced this design as the s.F.H.

1913. Upon this announcement it was also mentioned that the s.F.H.

1913 was considered a cooperative effort between Krupp and Rheinemetall.30

Presumably because much of the development of the variable recoil was

accomplished on the Rheinmetall side of the house this credit was given

by the APK. Krupp protested this statement, contending that they

had pioneered the variable recoil system.

An initial order for 360 s.F.H. “13’s was promised

to Krupp, of which 48 were to be delivered by October 1914. Upon

the outbreak of the war, the first of these were almost completed and

were in a short time fielded.31

Krupp along with other contractors, such as Rheinmetall and Spandau, produced

large numbers of these weapons during the war years.

|

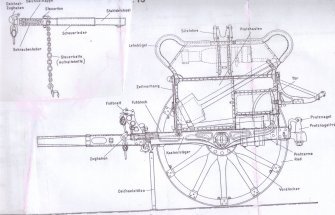

The “13” has a carriage much like the s.F.H.”02,

however, its spade could be fitted with a trail plate, which stopped the

spade’s blade from digging in more than necessary. This plate

was secured on brackets between the trail box and the opening in the box

trail. Its sight is fitted with a range drum, which determines quadrant

elevation. To the front of the trunnions are two spring equilibrators.

A shield is fitted to the howitzer and a hinge allows the top to fold

forward. A hood protects the area between barrel and the barrel

cut out in the shield. This hood has a notch through which a simple

direct fire metal sight can be viewed. The weapon has layer and

loader seats. The elevation and traversing handles can be reached

from the layer’s seat. The same short shell casings containing

a primer train are used in the “02” and “13”.

Also in the same way, bag charges and projectile are loaded to the front

of the shell case. Double acting brakes with cables that rap around

the hub and pull on a brake shoes and make contact with the wheel tire

are similar on all s.F.H. weapons. These brakes can be operated

by a man standing beside the weapon, or remotely, by a man mounted on

the limber using ropes. Scrollwork often found on s.F.H. “02’s

does not seem to be common, probably due to the fact that “13’s”

were almost all wartime production howitzers.

|

With the tremendous stresses put on the s.F.H. “13 design

in the early stages of the war one serious flaw was detected. Recuperator

springs failed and broke in very large numbers. Aggravating this

problem was the habit of firing batteries to over order replacement springs

to compensate for the expected problem. As a solution, Krupp suggested

fitting an air-recuperator to the s.F.H. 1913. Its design was closely

based on the Krupp air recuperator for the s.F.H. “02, which was

tested at Kummersdorf.32

After test had been conducted on an air recuperator it was introduced

in the spring of 1915 for use on the “13. With this modification,

the howitzer weight increased from 2135 kg. to 2175 kg. The recoil

which had travel from 1520 to 1030 mm., lengthened to 1565 to 1065 mm.

Elevation of 40 degrees increased to 41 degrees. Later, carriage

reinforcement was necessary which further increased the weight in firing

position to 2200 kg. and the ready to move weight of 2990 kg. This

was quite a contrast from the pre-war attitudes about howitzer weight,

when official weights were taken without paint. In the war years

50 to 100 kg. did not matter.33

Krupp had few problems converting to air recuperator production for the”13,

and in fact were able to deliver them to field units in an incredibly

short time. Rheinmetall had greater difficulty but were able to

meet the requirements with special effort. Other factories with

out expertise with air recuperators simply had to continue with the manufacture

of the “13 with spring recuperator.34

The first battery was provided with air recuperators in June of 1915.

Interestingly, there does not seem to be a way to tell, externally, if

an s.F.H. 1913 has the spring or the air recuperator. Also the type

of recuperator does not change the designation of the weapon. The

British played out an almost identical series of events. Their 18-pounder

Mark I also suffered the wartime malady of recuprator spring stress and

malfunction.

|

Generally the s.F.H. 1913 was a successful design with the total

number supplied by Krupp and Rheinmetall amounting to 3,409. Of

which, 2,676 were manufactured by Krupp and 733 by Rheinmetall.

An unknown number of “13s were also produced by other shops, such

as the Spandau in the author’s collection. Of these Herman

Schirmer’s reference notes only 252 were equipped with counterrecoil

springs and the remainder having the hydropneumatic counterrecoil mechanisms.

The level of acceptance this weapon achieved is evident in a 6 November

1917 letter sent to the Ministry of War by the Supreme Command of the

Army. In part reading “The heavy field howitzer 13 will continue

to be the mainstay of battle in this war.” Further, this letter

endorses the concept of organizing Foot Artillery Battalions with two

batteries of heavy field howitzers and one battery equipped with 10 cm.

field guns. Despite these positive words there was need for improvement

and modification in the “13.

(For more information and the foot notes see the "Development of the German 15cm." page.)

|

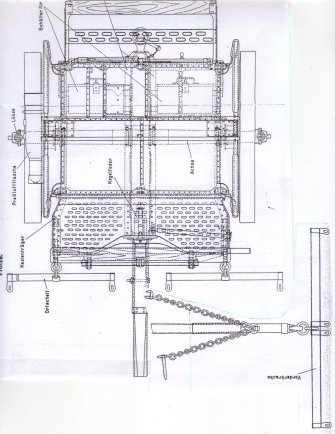

Above and Below are views of the sFH 13 and lg.sFH 13 limber

|